Mechanical properties

The first type of mastered production for rolling stock will be rough wheel pair with the maximum design axle load of 230.5 kN (RU1SH) and 245.2 kN (RV2SH) for freight wagons with design speed of 160 km/h.

Rough axis will be produced from continuous casting by hot deformation (forging and stamping), subjected to further heat treatment, to go through all kinds of tests required.

The entire production process is automated and carried axes with the latest technology, a feature of the new automated line is the ability to quickly transition to new and different kinds of forgings.

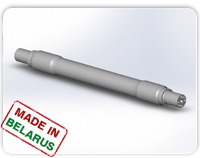

Wagon axle is one of the most critical parts of the bogie. It is a steel bar of circular cross section, which is strengthened wheel pair.

At first during the producing of wagon axle we get rough steel blank - rough axle, which exposed to heat and mechanical processing.The final product of producing is finishing axle.

All types of axles have the same distances between the centers of the load to the necks. It’s 2036 mm. For freight wagons with increased loads from wheel pair on rails up to 245 kN it provides split axle which has increased diameters.