| Constructions |

DIA, mm |

Lay length, mm | Lay direction | Linear density, g/m |

Breaking force, n. min |

Length cord

per spool Bs60, m |

Weigth of steel cord per spool Bs60, kg |

| Normal tensile | |||||||

| 4x6x0,25 HE | 1,93 | 4.3/8.5 | ss | 10,30 | 2300 | 1500 | 15,45 |

| 3+9+15x0,22+0,15 | 1,62 | 6.3/12.5/18/3.5 | sszs | 8,50 | 2600 | 2000 | 17,00 |

| 7x7x0,22+0,15 | 2,24 | 12.5/20/5 | szs | 15,20 | 4200 | 1100 | 16,72 |

| High tensile | |||||||

| 7x7x0,25+0,15 HT | 2,52 | 12.5/20/5 | szs | 19,80 | 5900 | 800 | 15,84 |

| 7x(3+9x0,245)±0,20 HT | 3,30 | 6.3/12.5/28/5 | zzsszs | 33,07 | 9000 | 450 | 14,88 |

| 7x(3+9+15x0,175)±0,20HT | 3,60 | 5/10/16/38/5 | ssszzzsz | 37,50 | 11160 | 375 | 15,84 |

*length and weight on the coil Bs40=Bs60; on the coil Bs80 twice as much as compared with Bs60

Steel cord is to be packed to cardboard boxes mounted onto transportation trays. Plastic separators are to be laid in layers inside the box for fixing the coils with the production. All products are to be put into a polyethylene bag. Plastic trays, separators and coils belong to multi-circulating reusable containers.

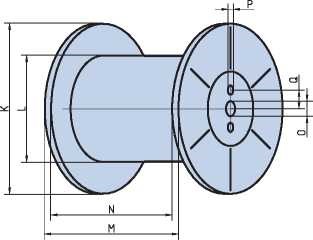

Spools

| Standard size | Designation | Bs 40 | Bs 60 | Bs 80/17 | Bs 80/33 |

| Diameter of flange, mm | K | 255 | 255 | 255 | 255 |

| Diameter of barrel, mm | L | 118 | 118 | 118 | 118 |

| Overall width, mm | M | 166 | 166 | 329 | 329 |

| Traverse, mm | N | 152 | 152 | 315 | 315 |

| Bore, mm | O | 17 | 33 | 17 | 33 |

| Number x diameter of drive hole, mm | P | 3х12,8 | 4х12,8 | 2х12,8 | 3х12,8 |

| Distance between center of drive hole and bore, mm | Q | 38 | 43 | 38 | 43 |

| Mass of a spool, kg | 2,18 | 2,29 | 2,47 | 2,51 |

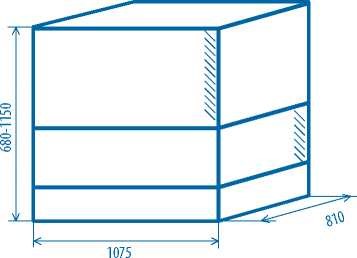

Packing box

Sizes of a packing box for 72 coils (Bs 40; Bs 60) or for 36 spools (Bs 80/17; Bs 80/33)

Pallets

| Sizes | Plastic trays | Wooden | |||

| A | B | C | G | ||

| Length | mm | 1100 | 1100 | 1100 | 1080 |

| Width | mm | 830 | 830 | 833 | 820 |

| Height | mm | 190 | 190 | 188 | 170 |

| Weight | kg | 15,15 | 25,5 | 22 | 22 |

Reusable containers

Method of spools Bs 40 or Bs60 (х100 pc) and Bs 80 (х60 pc) stacking for return